-

The DIF and DIT model duplex strainers have iron bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

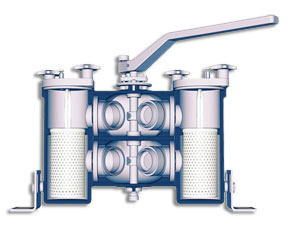

DIF & DIT IRON DUPLEX STRAINERSThe DIF and DIT model duplex strainers have iron bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

-

The DCF and DCT model duplex strainers have carbon steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

DCF & DCT CARBON STEEL DUPLEX STRAINERSThe DCF and DCT model duplex strainers have carbon steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

-

The DCF300 and DCT300 Class 300# model duplex strainers have carbon steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

DCF300 & DCT300 CARBON STEEL DUPLEX STRAINERSThe DCF300 and DCT300 Class 300# model duplex strainers have carbon steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

-

The DSF and DST model duplex strainers have stainless steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

DSF & DST STAINLESS STEEL DUPLEX STRAINERSThe DSF and DST model duplex strainers have stainless steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

-

The DSCF300 and DST300 Class 300# model duplex strainers have stainless steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

DSF300 & DST300 STAINLESS STEEL DUPLEX STRAINThe DSCF300 and DST300 Class 300# model duplex strainers have stainless steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Not recommended for steam service. 3/4" to 4" diameters.

-

The DBF and DBT model duplex strainers have superior aluminum bronze bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Suitable for potable water. Not recommended for steam service. 3/4" to 4" diameters.

DBF & DBT BRONZE DUPLEX STRAINERSThe DBF and DBT model duplex strainers have superior aluminum bronze bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Flanged and thread ends respectively. Suitable for potable water. Not recommended for steam service. 3/4" to 4" diameters.

-

The larger DIFL model duplex strainers have cast iron steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Not recommended for steam service. Special low torque design. 6" and 8" diameters.

DIFL CAST IRON DUPLEX STRAINERSThe larger DIFL model duplex strainers have cast iron steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Not recommended for steam service. Special low torque design. 6" and 8" diameters.

-

The larger DCFL model duplex strainers have cast carbon steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Not recommended for steam service. Special low torque design. 6", 8", & 10" diameters.

DCFL CARBON STEEL DUPLEX STRAINERSThe larger DCFL model duplex strainers have cast carbon steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Not recommended for steam service. Special low torque design. 6", 8", & 10" diameters.

-

The larger DSFL model duplex strainers have cast stainless steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Not recommended for steam service. Special low torque design. 6", 8", & 10" diameters.

DSFL STAINLESS STEEL DUPLEX STRAINERThe larger DSFL model duplex strainers have cast stainless steel bodies for use in continuous flow applications to avoid shutting down the system for cleaning. Not recommended for steam service. Special low torque design. 6", 8", & 10" diameters.

-

Stayflow fabricates high quality special duplex strainers in every configuration possible. 2" to 24" diameters.

FABRICATED DUPLEX STRAINERSStayflow fabricates high quality special duplex strainers in every configuration possible. 2" to 24" diameters.

Duplex Strainers

|

|

OVERVIEW: Stayflow Duplex Strainers are ideal when the piping stystem can not be shut down for basket cleaning. There are two screened baskets that trap debris, with a lever that switches between the two, allowing one basket to be cleaned with no interuption in flow - a benefit that is sometimes crucial. The duplex strainers (dual strainers) are available with threaded or flanged connections. These strainers are usually supplied in one of four materials: iron, carbon steel, bronze, or stainless steel. They are offered in 150# and 300# versions up to 4" size, and 150# to 8" sizes. Standard screens are provided for WOG (water, oil, gas) service, but other screens are available on request. |