-

The SF-IGA cast iron, full body swing check valve designed to AWWA C508 is a proven, durable, economical design that offers a flow path that is unobstructed. It normally comes equipped with a counter weight and lever for additional closure control, but is available without it for low head applications. 150# class. Buna-N seats, and cast iron discs. 2" to 12" diameters.

SF-IGA SWING AWWA C508 COUNTER WT CHECK VALVEThe SF-IGA cast iron, full body swing check valve designed to AWWA C508 is a proven, durable, economical design that offers a flow path that is unobstructed. It normally comes equipped with a counter weight and lever for additional closure control, but is available without it for low head applications. 150# class. Buna-N seats, and cast iron discs. 2" to 12" diameters.

-

The SF-IG cast iron, full body swing check valve is a proven, durable economical design that offers a flow path that is unobstructed. Purchase costs are economical 150# class. Buna-N seats, and cast iron discs. 2" to 12" diameters.

SF-IG1 SWING FULL BODY CI CHECK VALVEThe SF-IG cast iron, full body swing check valve is a proven, durable economical design that offers a flow path that is unobstructed. Purchase costs are economical 150# class. Buna-N seats, and cast iron discs. 2" to 12" diameters.

-

The AWWA Swing Check Valve is designed for municipal and industrial water and wastewater use, and can also be used for many other industrial applications. This top quality, conventional check valve complies with ANSI/AWWA C508 and MSS SP-71/MSS SP-136, and has a ductile iron body rated to 250psi. It provides a full selection of options for closure versatility, including various oil & air cushions, along with lever & weight or springs. 2" to 48" diameters.

AWWA C508 SWING CHECK VALVEThe AWWA Swing Check Valve is designed for municipal and industrial water and wastewater use, and can also be used for many other industrial applications. This top quality, conventional check valve complies with ANSI/AWWA C508 and MSS SP-71/MSS SP-136, and has a ductile iron body rated to 250psi. It provides a full selection of options for closure versatility, including various oil & air cushions, along with lever & weight or springs. 2" to 48" diameters.

-

Efficiency and reliability through simplicity of design is supplemented by the adjustable spring accelerator of the Slamblock Check Valve. The short disc stroke, flexing action of the valve's disc, and spring accelerator reduce the closing time of the valve reduce slam surges. Unmatched reliability is achieved by minimizing moving parts in this innovative design. Tested in accordance with AWWA C508. 2" to 48" diameters.

SLAMBLOCK SWING CHECK VALVEEfficiency and reliability through simplicity of design is supplemented by the adjustable spring accelerator of the Slamblock Check Valve. The short disc stroke, flexing action of the valve's disc, and spring accelerator reduce the closing time of the valve reduce slam surges. Unmatched reliability is achieved by minimizing moving parts in this innovative design. Tested in accordance with AWWA C508. 2" to 48" diameters.

-

The SF Industrial Thermoplastic Swing Check Valve is used in many chemical processing applications where a high volume of fluid transfer is required. It is available in PVC, CPVC, and Polypropylene. May be fitted with an optional counter balance device. Flanged bodies. 3/4" - 8" diameters.

SF PVC/CPVC/PP SWING CHECK VALVESThe SF Industrial Thermoplastic Swing Check Valve is used in many chemical processing applications where a high volume of fluid transfer is required. It is available in PVC, CPVC, and Polypropylene. May be fitted with an optional counter balance device. Flanged bodies. 3/4" - 8" diameters.

-

The DD PLUS is a versitile double disc swing check valves use spring assisted half-discs for up to 66" sizes. The wafer ends fit between ANSI 125/150# and Metric PN10/16 flanges. It is suitable for frequent flow reversals, but not fluids with solids. Includes many special features, including lead free and NSF certified for potable water applications. Meets AWWA C518 requirements, UL and FM Approved. 2" to 66" diameters.

DD PLUS DOUBLE DISC CHECK VALVEThe DD PLUS is a versitile double disc swing check valves use spring assisted half-discs for up to 66" sizes. The wafer ends fit between ANSI 125/150# and Metric PN10/16 flanges. It is suitable for frequent flow reversals, but not fluids with solids. Includes many special features, including lead free and NSF certified for potable water applications. Meets AWWA C518 requirements, UL and FM Approved. 2" to 66" diameters.

-

The DD-DW1 ductile iron body, lead free double disc swing check valves use spring assisted half-discs. The wafer style body design is compact, and it mates to 150# flanges. It is suitable for frequent flow reversals, but not fluids with solids. Buna-N, EPDM, or Viton seats, and aluminum-bronze or stainless steel discs. Lead free and NSF certified for potable water applications. API 594 dimensions. 2" to 24" diameters.

DD-DW1 DOUBLE DISC WAFER DI CHECK VALVEThe DD-DW1 ductile iron body, lead free double disc swing check valves use spring assisted half-discs. The wafer style body design is compact, and it mates to 150# flanges. It is suitable for frequent flow reversals, but not fluids with solids. Buna-N, EPDM, or Viton seats, and aluminum-bronze or stainless steel discs. Lead free and NSF certified for potable water applications. API 594 dimensions. 2" to 24" diameters.

-

The DD-CW carbon steel body, double disc swing check valves use spring assisted half-discs. The wafer style body design is compact, and is available in 150#, 300#, 600#, and 900# classes. It is suitable for frequent flow reversals, but not fluids with solids. Metal, Buna-N, EPDM, or Viton seats, and aluminum-bronze or stainless steel discs. 2" to 24" diameters.

DD-CW DOUBLE DISC WAFER CS CHECK VALVEThe DD-CW carbon steel body, double disc swing check valves use spring assisted half-discs. The wafer style body design is compact, and is available in 150#, 300#, 600#, and 900# classes. It is suitable for frequent flow reversals, but not fluids with solids. Metal, Buna-N, EPDM, or Viton seats, and aluminum-bronze or stainless steel discs. 2" to 24" diameters.

-

The DD-SW stainless steel body, double disc swing check valves use spring assisted half-discs. The wafer style body design is compact, and is available in 150#, 300#, 600#, and 900# classes. It is suitable for frequent flow reversals, but not fluids with solids. Metal or Viton seats, and stainless steel discs. 2" to 24" diameters.

DD-SW DOUBLE DISC WAFER SS CHECK VALVEThe DD-SW stainless steel body, double disc swing check valves use spring assisted half-discs. The wafer style body design is compact, and is available in 150#, 300#, 600#, and 900# classes. It is suitable for frequent flow reversals, but not fluids with solids. Metal or Viton seats, and stainless steel discs. 2" to 24" diameters.

-

The DD-CL carbon steel body, double disc swing check valves use spring assisted half-discs. The lug style body design can be used as a block valve, and it is available in 150#, 300#, 600#, and 900# classes. It is suitable for frequent flow reversals, but not fluids with solids. Metal, Buna-N, or EPDM seats, and stainless steel discs. 2" to 24" diameters.

DD-CL1 DOUBLE DISC LUG CS CHECK VALVEThe DD-CL carbon steel body, double disc swing check valves use spring assisted half-discs. The lug style body design can be used as a block valve, and it is available in 150#, 300#, 600#, and 900# classes. It is suitable for frequent flow reversals, but not fluids with solids. Metal, Buna-N, or EPDM seats, and stainless steel discs. 2" to 24" diameters.

-

The DD-SL stainless steel body, double disc swing check valves use spring assisted half-discs. The lug style body design can be used as a block valve and it is available in 150#, 300#, 600#, and 900# classes. It is suitable for frequent flow reversals, but not fluids with solids. Metal or Viton seats, and stainless steel discs. 2" to 24" diameters.

DD-SL1 DOUBLE DISC LUG SS CHECK VALVEThe DD-SL stainless steel body, double disc swing check valves use spring assisted half-discs. The lug style body design can be used as a block valve and it is available in 150#, 300#, 600#, and 900# classes. It is suitable for frequent flow reversals, but not fluids with solids. Metal or Viton seats, and stainless steel discs. 2" to 24" diameters.

-

The DD-DG ductile iron body, lead free double disc swing check valves use spring assisted half-discs. The wafer type ends fit between ANSI Class 125/150#, as well as PN10 and PN16 flanges. It is suitable for frequent flow reversals, but not fluids with solids. Lead free and NSF certified for potable water applications. Meets AWWA C518 requirements, UL and FM Approved. 2" to 12" diameters.

DD-DG DOUBLE DISC GROOVED END CHECK VALVEThe DD-DG ductile iron body, lead free double disc swing check valves use spring assisted half-discs. The wafer type ends fit between ANSI Class 125/150#, as well as PN10 and PN16 flanges. It is suitable for frequent flow reversals, but not fluids with solids. Lead free and NSF certified for potable water applications. Meets AWWA C518 requirements, UL and FM Approved. 2" to 12" diameters.

-

The economical DD-IW cast iron body, double disc swing check valves use spring assisted half-discs. The wafer style body design is compact, and it mates to 150# flanges. It is suitable for frequent flow reversals, but not fluids with solids. EPDM seats and stainless steel discs. 2" to 24" diameters.

DD-IW1 DOUBLE DISC WAFER CI CHECK VALVEThe economical DD-IW cast iron body, double disc swing check valves use spring assisted half-discs. The wafer style body design is compact, and it mates to 150# flanges. It is suitable for frequent flow reversals, but not fluids with solids. EPDM seats and stainless steel discs. 2" to 24" diameters.

-

The VCDD-P/H PVC & CPVC Butterfly Check Valves have minimum space requirements and, along with Swing Check Valves, are better for use with fluids containing solids or debris. Its limited travel results in very fast shut off. Flanged, Spigot, Male Thread, Wafer, & Grooved bodies. 2" - 24 diameters.

DD-P/H PVC/CPVC DOUBLE DISC CHECK VALVESThe VCDD-P/H PVC & CPVC Butterfly Check Valves have minimum space requirements and, along with Swing Check Valves, are better for use with fluids containing solids or debris. Its limited travel results in very fast shut off. Flanged, Spigot, Male Thread, Wafer, & Grooved bodies. 2" - 24 diameters.

-

The SIL-DW ductile iron body, center-guided silent check valves with straightener vanes work to eliminate water hammer. The wafer style body design is compact, and mates to 150# and 300# flanges. Buna-N and Viton seats and stainless steel and aluminum-bronze discs. FM approved. 2" to 12" diameters.

SIL-DW1 SILENT WAFER DI CHECK VALVEThe SIL-DW ductile iron body, center-guided silent check valves with straightener vanes work to eliminate water hammer. The wafer style body design is compact, and mates to 150# and 300# flanges. Buna-N and Viton seats and stainless steel and aluminum-bronze discs. FM approved. 2" to 12" diameters.

-

The SIL-SW stainless steel body, center-guided silent check valves with straightener vanes work to eliminate water hammer. The wafer style body design is compact, and mates to 150# and 300# flanges. Stainless steel seats and discs. 2" to 12" diameters.

SIL-SW1 SILENT WAFER SS CHECK VALVEThe SIL-SW stainless steel body, center-guided silent check valves with straightener vanes work to eliminate water hammer. The wafer style body design is compact, and mates to 150# and 300# flanges. Stainless steel seats and discs. 2" to 12" diameters.

-

The SIL-DG ductile iron body, center-guided silent check valves with straightening vanes work to eliminate water hammer. The globe style body design allows for minimal pressure loss, and incorporates integral flanges. 150# and 300# classes are offered. Stainless steel and aluminum -bronze seats and discs. FM approved. 2" to 24" diameters.

SIL-DG1/2 SILENT GLOBE DI CHECK VALVEThe SIL-DG ductile iron body, center-guided silent check valves with straightening vanes work to eliminate water hammer. The globe style body design allows for minimal pressure loss, and incorporates integral flanges. 150# and 300# classes are offered. Stainless steel and aluminum -bronze seats and discs. FM approved. 2" to 24" diameters.

-

The SIL-CG carbon steel body, center-guided silent check valves with straightening vanes work to eliminate water hammer. The globe style body design allows for minimal pressure loss, and incorporates integral flanges. 150# and 300# classes are offered. Stainless steel seats and discs. 2" to 24" diameters.

SIL-CG1/2 SILENT GLOBE CS CHECK VALVEThe SIL-CG carbon steel body, center-guided silent check valves with straightening vanes work to eliminate water hammer. The globe style body design allows for minimal pressure loss, and incorporates integral flanges. 150# and 300# classes are offered. Stainless steel seats and discs. 2" to 24" diameters.

-

The SIL-SG stainless steel body, center-guided silent check valves with straightening vanes work to eliminate water hammer. The globe style body design allows for minimal pressure loss, and incorporates integral flanges. 150# and 300# classes are offered. Stainless steel seats and discs. 2" to 24" diameters.

SIL-SG1/2 SILENT GLOBE SS CHECK VALVEThe SIL-SG stainless steel body, center-guided silent check valves with straightening vanes work to eliminate water hammer. The globe style body design allows for minimal pressure loss, and incorporates integral flanges. 150# and 300# classes are offered. Stainless steel seats and discs. 2" to 24" diameters.

-

The SIL-ST stainless steel body, center-guided silent check valves with thread ends work to eliminate water hammer. Viton seats. 3/8" to 3" diameters.

SIL-ST SILENT THREADED SS CHECK VALVEThe SIL-ST stainless steel body, center-guided silent check valves with thread ends work to eliminate water hammer. Viton seats. 3/8" to 3" diameters.

-

The SIL-BT economical bronze body, center-guided silent check valves with female thread ends work to eliminate water hammer. PTFE seats. 1/2" to 2" diameters.

SIL-BT SILENT THREADED BRONZE CHECK VALVEThe SIL-BT economical bronze body, center-guided silent check valves with female thread ends work to eliminate water hammer. PTFE seats. 1/2" to 2" diameters.

-

The economical SIL-IW cast iron body, center-guided silent check valves work to eliminate water hammer. The wafer style body design is compact, and mates to 125# and 250# flanges. Nickel plated iron or stainless steel seats and stainless steel discs. 2" to 10" diameters.

SIL-IW1 SILENT WAFER CI CHECK VALVEThe economical SIL-IW cast iron body, center-guided silent check valves work to eliminate water hammer. The wafer style body design is compact, and mates to 125# and 250# flanges. Nickel plated iron or stainless steel seats and stainless steel discs. 2" to 10" diameters.

-

The economical SIL-IG cast iron body, center-guided silent check valves work to eliminate water hammer. The globe style body design allows for minimal pressure loss, and incorporates integral flanges. 125# and 250# classes are offered. Nickel plated iron or stainless steel seats and stainless steel discs. 2.5" to 18" diameters.

SIL-IG SILENT GLOBE CI CHECK VALVEThe economical SIL-IG cast iron body, center-guided silent check valves work to eliminate water hammer. The globe style body design allows for minimal pressure loss, and incorporates integral flanges. 125# and 250# classes are offered. Nickel plated iron or stainless steel seats and stainless steel discs. 2.5" to 18" diameters.

-

The SIL-PT PVC In-Line Adjustable Spring Check Valve allows adjustment of the spring for control of back pressure in system, reducing water hammer, and preventing siphoning. Easily adjusts to hold back from 5 to 32 feet of pressure head, 1 psi (2.3 feet of head) for each full turn of the adjustment screw. It is ideal for landscape and irrigation applications, and quickly installs with space saving in-line design. 1/2" - 1" diameters.

SIL-PT PVC ADJUSTABLE SPRING CHECK VALVEThe SIL-PT PVC In-Line Adjustable Spring Check Valve allows adjustment of the spring for control of back pressure in system, reducing water hammer, and preventing siphoning. Easily adjusts to hold back from 5 to 32 feet of pressure head, 1 psi (2.3 feet of head) for each full turn of the adjustment screw. It is ideal for landscape and irrigation applications, and quickly installs with space saving in-line design. 1/2" - 1" diameters.

-

The SS-DW ductile iron swing check valves is an economical design with a flow path that is unobstructed. The wafer style body design is compact and light. Buna-N seats, and stainless steel discs. 2" to 12" diameters.

SS-DW1 SWING WAFER CI CHECK VALVEThe SS-DW ductile iron swing check valves is an economical design with a flow path that is unobstructed. The wafer style body design is compact and light. Buna-N seats, and stainless steel discs. 2" to 12" diameters.

-

The SS-SW stainless steel swing check valves is an economical design with a flow path that is unobstructed. The wafer style body design is compact and light. PTFE seats, and stainless steel discs. 2" to 12" diameters.

SS-SW1 SWING WAFER SS CHECK VALVEThe SS-SW stainless steel swing check valves is an economical design with a flow path that is unobstructed. The wafer style body design is compact and light. PTFE seats, and stainless steel discs. 2" to 12" diameters.

-

The SS-CW carbon steel swing check valves is an economical design with a flow path that is unobstructed. The wafer style body design is compact and light. Viton seats, and stainless steel discs. 2" to 12" diameters.

SS-CW1 SWING WAFER CS CHECK VALVEThe SS-CW carbon steel swing check valves is an economical design with a flow path that is unobstructed. The wafer style body design is compact and light. Viton seats, and stainless steel discs. 2" to 12" diameters.

-

The SP-CW zinc-plated carbon steel swing check valves is a simplified, economical design with a flow path that is unobstructed. The narrow wafer style body design is very compact and flange gaskets are not required due to the built-in, body seal o-rings. Buna-N seats, and stainless steel discs. 2" to 12" diameters.

SP-CW1 SWING SHORT WAFER CS CHECK VALVEThe SP-CW zinc-plated carbon steel swing check valves is a simplified, economical design with a flow path that is unobstructed. The narrow wafer style body design is very compact and flange gaskets are not required due to the built-in, body seal o-rings. Buna-N seats, and stainless steel discs. 2" to 12" diameters.

-

The SP-SW stainless steel swing check valves is a simplified, economical design with a flow path that is unobstructed. The narrow wafer style body design is very compact and flange gaskets are not required due to the built-in, body seal o-rings. PTFE seats, and stainless steel discs. 2" to 12" diameters.

SP-SW1 SWING SHORT WAFER SS CHECK VALVEThe SP-SW stainless steel swing check valves is a simplified, economical design with a flow path that is unobstructed. The narrow wafer style body design is very compact and flange gaskets are not required due to the built-in, body seal o-rings. PTFE seats, and stainless steel discs. 2" to 12" diameters.

-

The VCYY-P/H Y PVC Gray, PVC Clear & CPVC Y-Check Valves are an angle type valve that automatically stops reverse flow by the dead weight of the disc plug. Y-checks are less affected by turbulent flow and typically have lower shutoff characteristics than ball checks, and also have improved flow characteristics. In-line clean out. Socket, SR Threaded or Flanged end connections, plus True Union styles available. 1/2" - 4" diameters.

VCYY-P/H PVC/CPVC Y TYPE CHECK VALVESThe VCYY-P/H Y PVC Gray, PVC Clear & CPVC Y-Check Valves are an angle type valve that automatically stops reverse flow by the dead weight of the disc plug. Y-checks are less affected by turbulent flow and typically have lower shutoff characteristics than ball checks, and also have improved flow characteristics. In-line clean out. Socket, SR Threaded or Flanged end connections, plus True Union styles available. 1/2" - 4" diameters.

-

One of the most versatile valve designs available, the BL-P/H PVC & CPVC True Union Industrial Ball Check Valves provide maximum versatility with fully interchangeable valve cartridges. NSF Certified for potable water service. Low profile design for applications with fluids free from debris and solids. 1-1/2" - 4" diameters.

BL-P/H PVC/CPVC TRUE UNION BALL CHECK VALVEOne of the most versatile valve designs available, the BL-P/H PVC & CPVC True Union Industrial Ball Check Valves provide maximum versatility with fully interchangeable valve cartridges. NSF Certified for potable water service. Low profile design for applications with fluids free from debris and solids. 1-1/2" - 4" diameters.

-

The Model TDV Triple Duty Valve is three products in one, as it takes the place of a balance valve, shut-off valve, and check valve. This spring-loaded valve can be adjusted from full flow to complete shut-off. A graduated position indicator allows easy adjustment and flow control, and its automatic shut-off helps prevent water hammer. 2" to 20" diameters.

TDV TRIPLE DUTY VALVEThe Model TDV Triple Duty Valve is three products in one, as it takes the place of a balance valve, shut-off valve, and check valve. This spring-loaded valve can be adjusted from full flow to complete shut-off. A graduated position indicator allows easy adjustment and flow control, and its automatic shut-off helps prevent water hammer. 2" to 20" diameters.

-

The Flexicraft Rubber Duckbill check valves are an efficient way to control back pressure from sewage treatment plants, outfalls, and tidal operations. Series CPF flanges directly to pipes, storm water headwalls, and Series CPO directly clamps. Series CPI mounts between existing flanges, and Series COJ flanges into systems with a full metal body jacket.

RUBBER DUCKBILL CHECK VALVEThe Flexicraft Rubber Duckbill check valves are an efficient way to control back pressure from sewage treatment plants, outfalls, and tidal operations. Series CPF flanges directly to pipes, storm water headwalls, and Series CPO directly clamps. Series CPI mounts between existing flanges, and Series COJ flanges into systems with a full metal body jacket.

Check Valves

OVERVIEW: Check valves open with forward flow, and automatically return to close against reverse flow. The main function is to protect mechanical equipment, most notably pumps, where back flow can damage the internal components. Check valves may be grouped according to the way the closure member moves onto the seat.

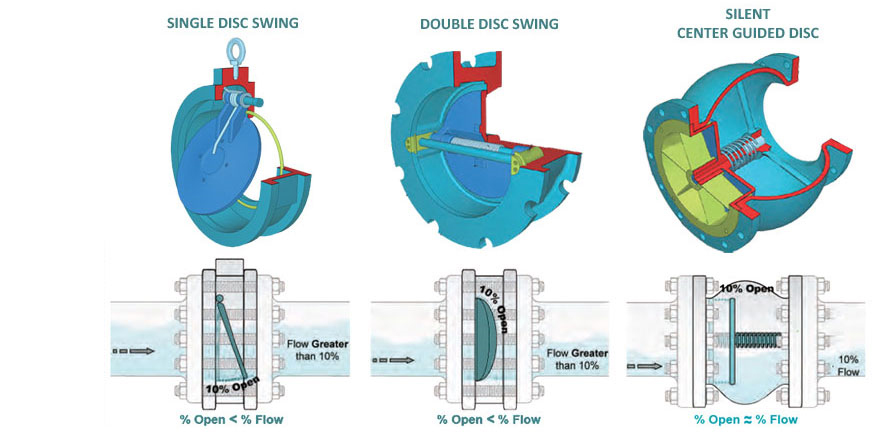

The Swing Check Valve has a flat disc that pivots or swings about a hinge pin. They are low cost, and have low head loss characteristics when fully open. But because of the long stroke and inertia of the disc, the traditional swing check valve may slam in vertical pipe installations. These valves are therefore sometimes outfitted with a lever and weight accessory. They can handle liquids with solids such as wastewater.

The most compact swing check valve is the Double Disc Check Valve (aka dual disc). The body is usually a wafer design (fits between two pipe flanges) and it has a hinge pin about which two opposing D-shaped discs rotate. The closure is assisted by a torsion spring which wraps around the hinge pin. It is not used in wastewater containing solids, as spokes that run across the body can collect debris. Advantages are it is small and light, and it has short travel and quick plate closing reducing slamming and make it more suitable for frequent flow reversals. A drawback is a higher resistance to flow because the plates are always in the flow path. Best for clean liquids.

Another type is the center guided lift Silent Check Valve. These in line check valves have spring-loaded discs which move along the pipe axis over a short distance to close automatically in a fraction of a second. Because of their fast closure, these check valves rarely slam and hence have earned the name "silent". They are simple, automatic, and cost effective but can result in higher energy costs in the long run. They can be economical to produce and reliable in operation. Silent check valves are commonly used in high-rise buildings and high head applications because of their quiet closure. Best for clean liquids.

Quick closure is the key to water hammer prevention, so it is important to consider the speed the check valve will close. And as illustrated here, in addition to its speed of closure, a center guided silent check valve that is almost closed will only have a small amount of reverse flow, so water hammer is not as likely for that reason as well. Conversely, a single disc or double disc swing check valve's proportional flow rate may be greater than than its percentage open, meaning more reverse flow is present.